Building Information Modeling (BIM) has transformed how UK AEC teams deliver projects yet something is still missing. Even with 3D models and common data environments, major infrastructure programmes continue to suffer from design coordination headaches and quality slip-ups.

If you’ve ever been in a BIM coordination meeting for a megaproject, you know the pain: inconsistent models, last-minute design errors, and endless manual checks. The “missing layer” in today’s BIM workflows is automated design validation at scale – a way to continuously verify that models meet requirements, without relying solely on human eyes. This article explores why that gap exists, the impact it’s having (with real examples like HS2), and how the industry is starting to fill it.

HS2: A Case Study in Design Governance Challenges

Take High Speed 2 (HS2), the largest UK infrastructure project, as a cautionary tale. HS2 is being delivered by multiple joint ventures (including firms like AtkinsRéalis), which makes maintaining a unified design governance framework incredibly difficult. Each JV brings its own tools, standards, and workflows.

As Lawrence Chapman, HS2’s Lead Information Manager, noted, the project’s supply chain is wide and varied in BIM maturity – not everyone follows the latest ISO 19650 standards, and data comes in many formats. The result? Even with a strong client organization, ensuring consistency across all designs and data exchanges is a constant battle.

AtkinsRéalis has been supporting HS2 by managing technical standards and design integration across Phase 1 and 2a, effectively acting as HS2’s “first line of defence” in technical assurance. Yet, governing a single source of truth across dozens of designers and contractors is a massive undertaking. HS2’s experience shows that when everyone is running parallel BIM workflows, catching data misalignments or compliance gaps is like finding needles in multiple haystacks.

Manual Model Checking: The Unsustainable Status Quo

Ironically, many “digitally mature” AEC firms in the UK still fall back on very manual quality assurance (QA) processes for BIM. It’s common to see teams conducting QA by visually inspecting models, marking up PDFs, and holding endless calls to double-check details – essentially the same approach from the paper-and-2D era, just applied to 3D models.

Studies confirm that traditional manual compliance checking is “time-consuming, costly and error-prone,” with researchers calling manual design inspections highly “inefficient”. Despite investments in BIM coordination software, much of the QA burden still rests on senior staff who know what to look for. As projects scale up, relying on a handful of experts to catch every modeling mistake or standards violation just doesn’t scale. It’s unsustainable to depend on heroics and overtime from specialist staff to keep models clean.

The High Cost of Design Errors and “Bad Data”

Why does this issue deserve urgent attention? Because design errors and data misalignments aren’t just paperwork problems – they translate directly into rework and cost overruns. Industry estimates (from the Construction Industry Institute and others) indicate that construction rework can quietly consume anywhere from 5% to 20% of a project’s cost, averaging around 12%. On a £1 billion project, that’s like £120 million going to waste on do-overs. A significant share of this rework is driven by flawed design information.

Fragmented Workflows and Inconsistent Data

Part of the challenge lies in how project teams are structured on big jobs. Joint ventures and multi-party delivery models (common in UK infrastructure) often mean each partner has its own BIM standards or naming conventions. Data silos emerge, and models might not integrate neatly.

On HS2, for example, the various design JV teams had to coordinate not just with the client (HS2 Ltd) but with each other all while adhering to evolving standards. It’s easy to see how “one version of the truth” can splinter. A change in one section’s model might not register with another section’s team until a formal coordination meeting weeks later. Parallel BIM workflows running on different CDEs or software versions make real-time oversight tricky. This is why HS2 established integrated project teams and a “hands off, eyes on” technical assurance approach – to empower JVs to make decisions, but still keep an eye on the big picture.

Even so, data inconsistencies are hard to catch when they’re buried in thousands of model files across dozens of contracts. The governance frameworks need to align, or else one JV might be modeling to a slightly different rule set than another. These fragmented processes underscore the need for an automated way to check for consistency, compliance, and coordination issues continuously, across the whole programme, not just within each silo.

From “Model Creation” to “Model Verification”

All of these pain points are driving a fundamental shift in mindset for leading firms: from focusing purely on model creation to emphasizing model verification – it’s not enough to produce a detailed BIM model – you also have to prove that the model fulfills the design intent and meets regulatory requirements. And you need to prove it earlier.

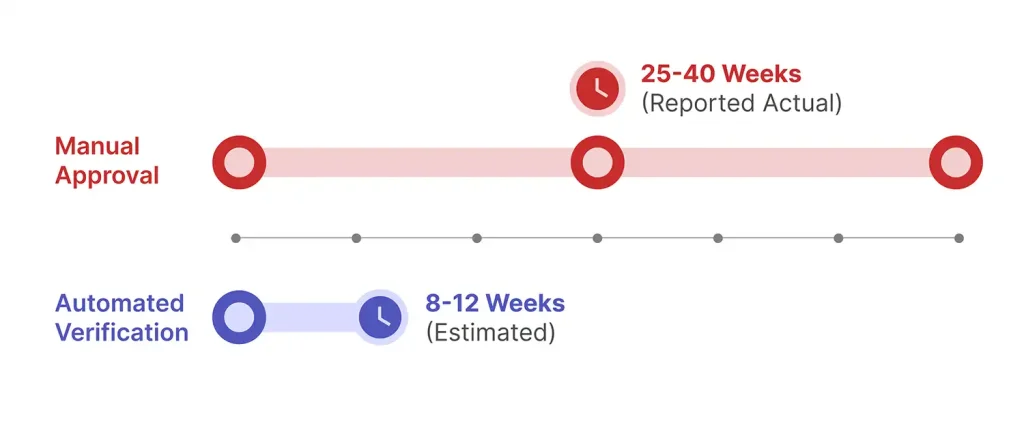

Recent UK regulations like the Building Safety Act 2022 reinforce this shift. Under the Act’s new gateway regime for higher-risk buildings, design teams must submit digital information to the Building Safety Regulator (BSR) to demonstrate compliance before construction begins (Gateway 2) and again before occupancy (Gateway 3). If you just hand over drawings and BIM files without clear evidence that they comply with building regs, your approval can be delayed or rejected.

In practice, BSR approvals that were supposed to take 8-12 weeks are taking 25-40 weeks, with some projects facing 18-month delays. One common mistake is that applicants simply submit plans and specs “which merely show what work is to be carried out” – instead of explicitly showing how the design complies with each regulation.

The Emergence of Automated Design Validation

So how do we add this missing layer of verification without slowing projects down? The good news is that technology is catching up. A new generation of tools is emerging to run automated design checks at scale effectively acting as a continuous “spell-check” for BIM models. These systems go beyond clash detection, checking building regulations, client standards, and alignment with design intent in real time rather than weeks later through manual review.

The goal isn’t to replace human expertise, but to augment it. Automated validation cross-checks thousands of elements against hundreds of requirements, so senior engineers can focus on design decisions rather than repetitive checking. As these systems evolve, they’re increasingly able to identify coordination issues that would otherwise slip through.

Our team at Tektome, for example, is building AI-driven tools designed to continuously verify BIM models for compliance, consistency, and quality. The ambition is simple: embed a digital co-pilot into the workflow that helps prevent errors early reducing rework and improving project efficiency before problems reach the site.

Conclusion

The UK AEC industry is entering a new phase. After years focused on BIM adoption, attention is shifting towards making models truly trustworthy at scale. Leaders at firms like AtkinsRéalis are recognising that coordination, governance, and QA must evolve beyond slow, manual checks. Projects like HS2 highlight both the complexity of the challenge and the opportunity: stronger design governance, fewer errors, and faster delivery.

Automated checking technologies are beginning to fill this gap. Our team at Tektome is developing tools to make design verification systematic and scalable. If you’re interested in trying it out yourself as soon as the product is launched, leave your details in the form below and we’ll get in touch with you as soon as the product is launched.