Building Information Modeling (BIM) has transformed how teams design projects, but quality assurance (QA) is struggling to keep up. Many AEC project managers still discover design errors late in the game, face poor visibility into issues as designs evolve, and juggle requirements scattered across silos.

Add in clunky tools and manual checking, and it’s no wonder QA feels like a constant headache. Sound familiar? The good news is that a major shift in BIM quality control is on the horizon – one that promises to catch errors earlier, continuously monitor quality, and even understand what you meant to design. Here’s what you need to know.

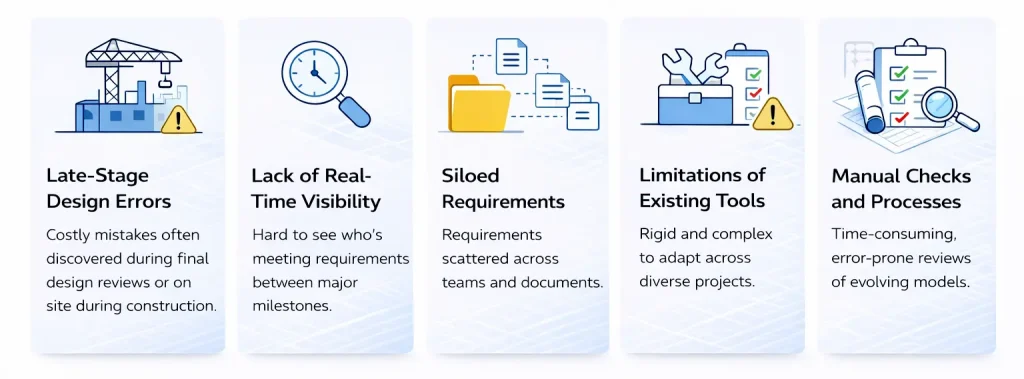

Key BIM Quality Challenges Today

Let’s quickly recap the common pain points in today’s BIM QA workflows, which many project managers and consultants in the UK/EU will recognise:

- Late-Stage Design Errors: Too often, mistakes aren’t caught until final design reviews or on site during construction. By then the fix is expensive and disruptive. Studies show that the later a design error is discovered, the more it costs – one analysis estimated design mistakes add up to $865 billion in extra costs globally each year.

- Lack of Real-Time Visibility: There’s usually no easy way to see in real time if the model meets all requirements. Many teams rely on periodic manual audits or hope that no news is good news. This leaves project managers flying blind for long stretches – you only find out about an issue after it has grown into a bigger problem.

- Siloed Requirements: Project requirements come from everywhere – client briefs, regulations, internal standards, contracts – and they often live in separate documents or different teams’ heads. This siloed setup means important requirements can be missed or misunderstood. A lack of communication among stakeholders can cause the design to “fail to reflect intended requirements accurately”.

- Limitations of Existing Tools: Yes, there are software tools for clash detection and rule checking, however, these tools usually catch basic issues (e.g. geometry clashes) but struggle with project-specific requirements or more nuanced checks.

- Manual Checks and Processes: Despite all our tech, a lot of QA is still done by hand – think visual inspections of models, marking up PDFs, and endless Zoom meetings to double-check details. This is slow, tedious, and error-prone. In fact, studies have found that manual compliance checking is “time-consuming, costly and error-prone”. One scientific review noted traditional manual inspections are often “inefficient”. And when designs change frequently (50+ revisions isn’t unheard of on big jobs), manually re-checking everything becomes chaotic.

The Next Shift: Continuous, AI-Powered QA That Understands Intent

Imagine a BIM quality process that works more like spell-check in Word – continuously running allowing you to discover issues as you design. This is the vision for the next shift in BIM quality: an AI-driven, always-on “digital QA assistant” that catches errors early and often. Here’s what this looks like:

- Continuous Checking: Instead of waiting for designated QA stages, automated checks run throughout the project. The moment a designer updates the model, the system can flag non-compliance or errors. This means no more nasty surprises late in design – issues are caught when they’re still easy and cheap to fix. Project managers get real-time visibility into model health, almost like a dashboard for quality.

- Intent-Aware AI: The real game-changer is AI that understands what you’re trying to achieve. Traditional rule-based checkers only look for hard-coded criteria; an intent-aware AI can interpret natural language descriptions of requirements or questions. For example, you could simply ask the system: “Are any of our fire exit corridors too narrow?” or “Highlight rooms near the electrical riser that might need wet cleaning.” The AI interprets your request and scans the model to find answers.

- Consistent and Scalable: With AI applying rules uniformly, you get consistent results no matter who runs the check. Ambiguities drop since the machine doesn’t get “interpretation fatigue.” And whether your model has 100 elements or 100,000, the effort to check is the same push-button process. The heavy lifting is handled by an algorithm that doesn’t sleep or lose focus.

In short, this new approach means QA moves from a periodic, reactive task to a continuous, proactive safety net. It’s like having a diligent inspector looking over your team’s shoulder at all times, but one that works at computer speed and never misses a thing.

How Tektome Is Solving These Challenges

At Tektome, we’re building something new – a next-generation tool designed to solve the quality challenges that project teams face every day. It’s still under wraps, but here’s a preview of what you can expect.

- Automated Checks: The tool will perform automated quality and compliance checks on your BIM models with minimal setup. Think of it like pressing a “check my model” button. Code compliance, space standards, clash detection – all covered, early and often.

- Natural Language Interaction: You won’t need to script or code to use it. Simply describe what you want to check in plain English – for example: “Highlight any doors that don’t meet fire regs on each floor,” or “Flag any coordination issues in the plant room.” The AI interprets your request and gets to work.

- Seamless BIM Integration: The tool will plug into the BIM workflows you already use. It’s designed to work with Revit models and IFC files, acting as an assistant within your design environment. Requirements from regulations, client briefs, or internal standards can be centralised and continuously checked, so everyone’s aligned and quality doesn’t slip through the cracks.

This solution is being developed by architects and AI specialists at Tektome who’ve lived through the same frustrations. As the team put it: “We’re as frustrated with today’s manual QA grind as you are and we’re doing something about it.” The aim isn’t to replace the human touch, but to amplify it – freeing up project managers to focus on strategy and intent, not spreadsheets and checklists.

Embracing the Future of BIM Quality

The bottom line? BIM quality control is about to get smarter. No more last-minute surprises. No more hours lost in QA admin. With AI-enabled tools like the one we’re developing, you’ll soon have a continuous, intelligent QA partner built into your process.

👉 Want to be first to know when it’s live? Leave your details below to register your interest. You’ll get launch updates, early access benefits, and a front-row seat to the next shift in BIM quality.