When a construction project runs into costly rework or delays, the culprit is something that should have been caught much earlier. Incomplete or delayed BIM model quality assurance (QA) and compliance checks are emerging as a major risk for modern construction firms.

This post explores how “small” BIM errors can snowball into big problems, why traditional checking methods aren’t enough, and how new approaches like natural-language model checking can help construction companies in the UK and Europe protect their margins.

Design Errors Upstream, Contractor Costs Downstream

A design detail quite often is overlooked or miscommunicated in the consultant’s BIM model, and only discovered once construction is underway. By then, the construction team is left to sort it out, often through expensive rework, schedule extensions, or both. In theory, design errors originate with architects or engineers, but in practice contractors frequently absorb the fallout. As one industry analysis put it,

Rework isn’t just a site-side issue – it’s a symptom of design or communication failure.

When design assumptions misalign or documentation is unclear, the result is “delays, mistrust among stakeholders and budget overruns” on site.

These hidden costs are significant. Studies have found that design-related issues can contribute 5-20% of total project costs in rework, and nearly 90% of that rework is preventable with better processes. What’s more, research indicates roughly 40% of construction problems trace back to design phase errors. The later those errors are discovered, the more expensive they become to fix. Contractors end up footing the bill through extra labor, idle time, and hit to their own margins – even when the mistake originated in someone else’s model.

Why Traditional BIM Checks Aren’t Enough

While most firms perform basic model checks, they typically focus on geometry clashes and manual reviews. This approach is insufficient; a model can be “clash-free” yet still violate building regulations or client requirements.

The Limits of Manual QA

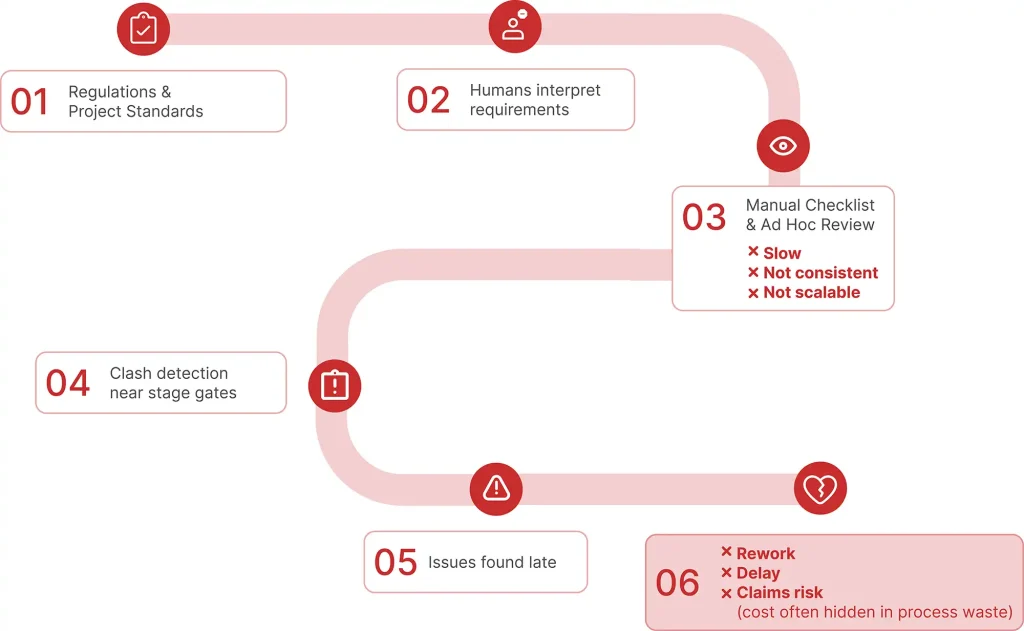

Traditional quality control is plagued by several critical flaws:

- Scalability: Manual checking is slow and costly. In large projects with thousands of elements and 50+ revisions, human reviewers simply cannot keep pace.

- Inconsistency: Teams often rely on spot-checks and individual experience, leading to subjective results where different reviewers catch different errors.

- Functional Blind Spots: Standard clash detection identifies overlapping physical objects but fails to catch “soft” violations, such as insufficient door clearances or missing fire ratings.

Beyond Geometry

As one industry leader noted, true BIM QA ensures data integrity across the entire project lifecycle. Relying solely on manual oversight and clash scans is a high-risk strategy that often leaves regulatory and quality issues undiscovered until they become expensive on-site problems.

Clash detection is not the same as compliance checking. Without automated rule-based audits, you aren’t truly managing project risk.

Without automatic BIM checking:

Hidden Risks from Inconsistent Standards

Another challenge is inconsistency across teams. On many projects, each subcontractor or consultant has their own BIM standards, naming conventions, and ways of structuring models. The result is a fragmented approach where data doesn’t line up neatly – and that creates hidden risks and blind spots for the main contractor.

A recent PlanRadar survey found “different standards across sites and trades” was the most common quality issue cited (by 56% of respondents). More than three-quarters of firms reported that documentation and models vary from project to project, and over half admitted they lack enforceable processes to keep things consistent. In practice, this inconsistency “pushes costs into the shadows and exposes projects to cascading disruption – from rework and schedule slippage to disputes and warranty claims”.

When Requirements Get Lost in Translation

Even when models are consistent, there’s still the human factor: differing interpretations of regulations or client requirements between stakeholders. Building codes and employer’s requirements can be complex and sometimes open to interpretation. One checker might interpret a fire safety rule one way, while another person reads it differently – and the discrepancy may not surface until much later. A 2023 study observed that as BIM models grow more complex, manual reviews lead to ambiguity and inconsistency in design assessments. Put simply, two people can look at the same model and not agree on whether it complies.

Miscommunication plays a big role here. If a client’s requirement isn’t clearly conveyed to all designers and subcontractors, it may never make it into the model correctly. According to research compiled by Tektome, a major cause of design errors is “lack of communication” among project stakeholders – when designers, contractors, and clients aren’t on the same page, the design can fail to reflect the intended requirements. Likewise, differing assumptions about regulations lead to elements that don’t satisfy one party’s understanding of the rules. These gaps in understanding often aren’t discovered until a formal review or, worse, during a statutory approval or inspection. By that point, teams have to scramble to make changes under time pressure, which again means extra cost and delay.

Natural-Language Model Checking – A Smarter Approach

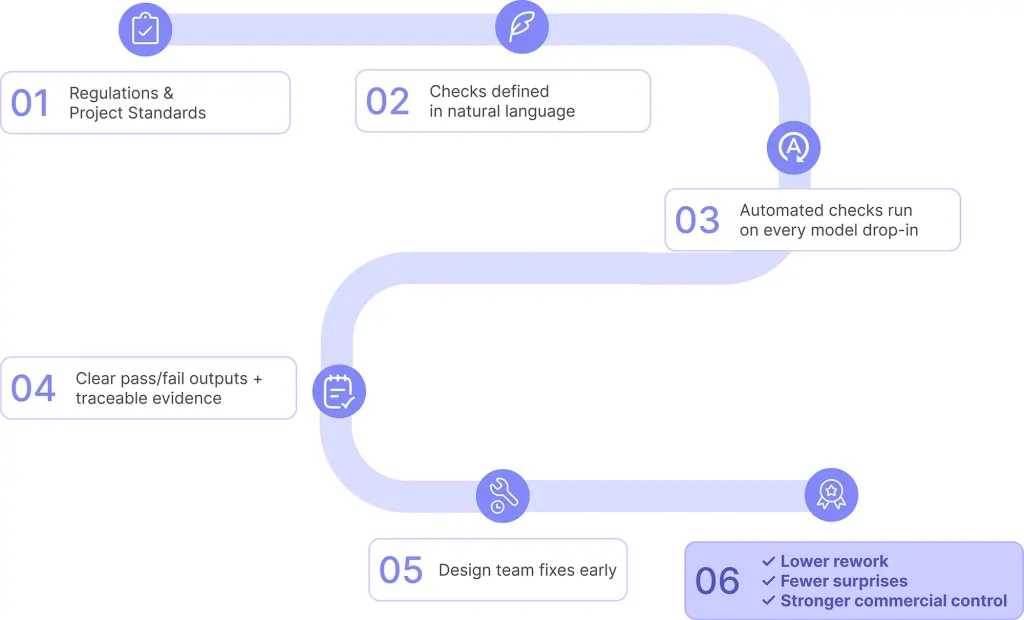

How can construction firms close these gaps? One promising development is natural-language model checking. The idea is simple but powerful: instead of writing complex scripts or manually inspecting the model for each requirement, you let project teams define rules in plain English (or any human language). The system’s AI can interpret those rules and automatically check the BIM model against them. For example, imagine typing a rule that says: “All door openings in fire escape routes must be at least 900mm wide and have a 30-minute fire rating.” A natural-language checking tool would parse that and scan every door in the model to see if it meets those criteria – flagging any that don’t.

The beauty of this approach is its accessibility and agility. Project requirements evolve, regulations get updated, clients add new rules with a natural-language system – updating the rule is as easy as editing a sentence. There’s no need for a BIM manager to write a new script or spend hours setting up a bespoke check. This lowers the barrier to performing comprehensive checks early and often. It also means more people on the team (not just software specialists) can contribute to defining quality and compliance rules.

Essentially, it brings QA out of the backroom and into the day-to-day toolkit of the delivery team. Natural-language model checking harnesses advances in AI to bridge the gap between human intent and machine precision. The computer handles the heavy lifting of scanning the model, while humans provide oversight and judgment.

With automatic BIM checking:

Model Checking as a Necessity, Not a Luxury

For forward-thinking construction firms, these kinds of intelligent, scalable model checks have moved from a “nice-to-have” to a necessity. Margins are tight, schedules are unforgiving, and regulatory scrutiny is higher than ever in the UK and Europe. Relying on outdated, manual QA practices is increasingly seen as an unacceptable risk. In fact, industry leaders are calling for a shift toward proactive digital QA.

“The industry recognises that consistent QA/QC is fundamental to profitability, yet most firms are struggling with the practical execution,”

notes Rob Norton, UK Director at PlanRadar. His advice: move beyond paper-based, ad-hoc processes and adopt unified digital standards that teams can follow consistently across every site and trade. In essence, make quality checks systematic and tech-enabled, not dependent on heroics and last-minute fixes.

A Solution to Future-Proof Your QA

At Tektome, we’ve been working on exactly these challenges and are developing an automated BIM model checking solution designed to address them. The platform enables project teams to define QA rules in natural language and automatically apply them across BIM files, whether in Revit, IFC, or other formats. Building regulations, employer’s requirements, and internal standards can be translated into plain-English checks without scripting or specialist tools. The system’s AI interprets those rules and scans models for non-compliance, flagging issues across disciplines.

It is built to handle inconsistent standards, reducing blind spots caused by naming variations or missing data. Unlike traditional clash detection, it can assess more complex requirements such as spatial clearances, accessibility criteria, or fire compliance. By identifying risks early, it helps reduce rework, coordination changes, and QA costs before they affect programme or margin.

Conclusion and Next Steps

Incomplete or late BIM model checks are not minor workflow issues – they represent a direct risk to programme, compliance and profitability. Across the UK and Europe, construction firms are recognising that manual QA processes and fragmented standards can no longer cope with increasing project complexity and regulatory pressure. The opportunity now lies in adopting scalable, intelligent model checking, where requirements can be defined in plain language and automatically verified, allowing teams to identify issues early and prevent costly rework and delay.

This is a practical risk management for today’s projects. We are developing a solution designed to help construction teams carry out comprehensive, continuous BIM QA across their project data, turning compliance checking into a proactive safeguard rather than a late-stage firefight. If you are looking to strengthen your model verification processes and reduce downstream risk, we invite you to register your interest using the form below.